PLC Control

7" Touch Panel

Low Energry Cost

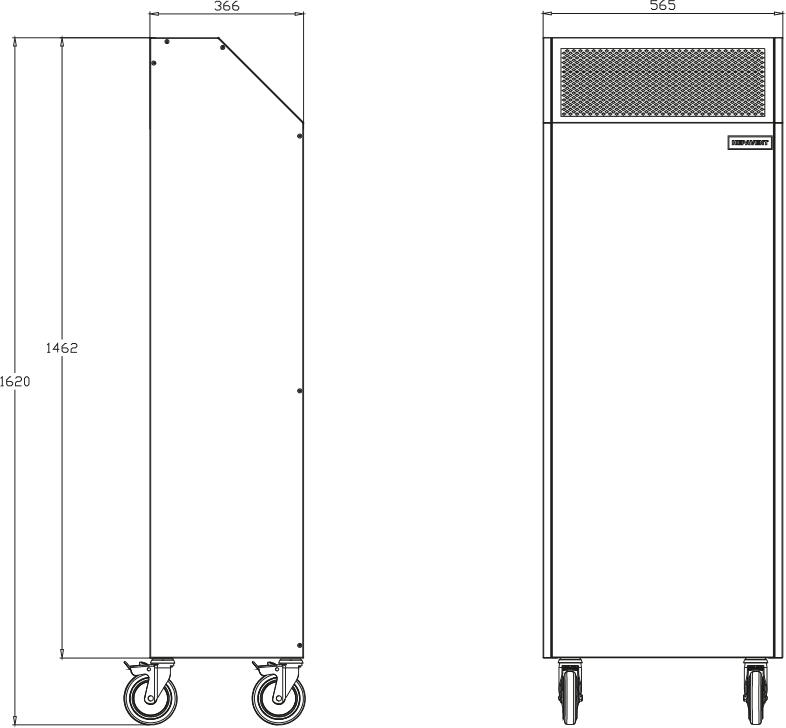

Compact Design

Plug and Play

Low Sound Level

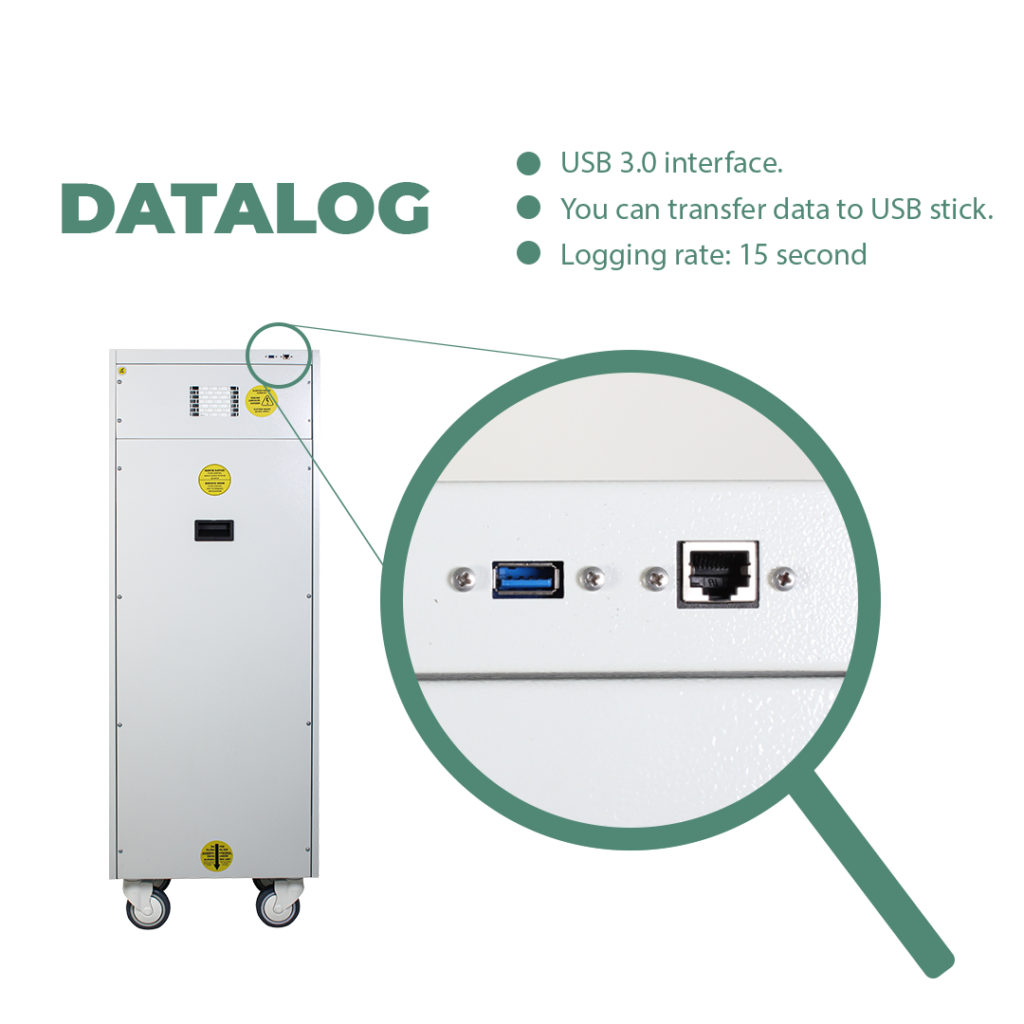

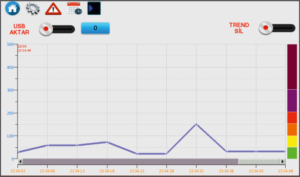

Datalog

Datalog

Well Filtering

Radial EC Fan

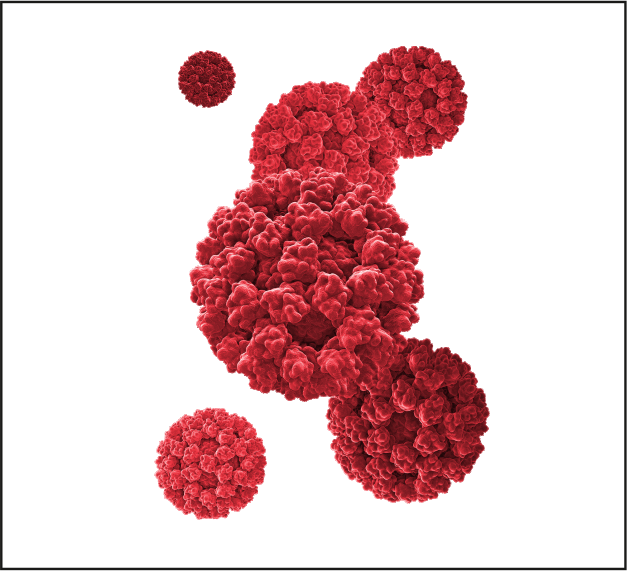

Effectiveness At Inactivating 99,95% OF

VIRUSES AND BACTERIA ON FIRST PASS

Protect employees health in health facilities

Prevents microbial contamination

Reduce cross contamination

Suggested for food product contact to Improve product shelf life

Reduce PM1 and PM2.5 , Less Asthma and Allergy Suffering

Healthier Indoor Environment, Less Odour

Completely Silent , Low Power Consumption

Meets WHO / CDC / ECDC air filtration guidelines

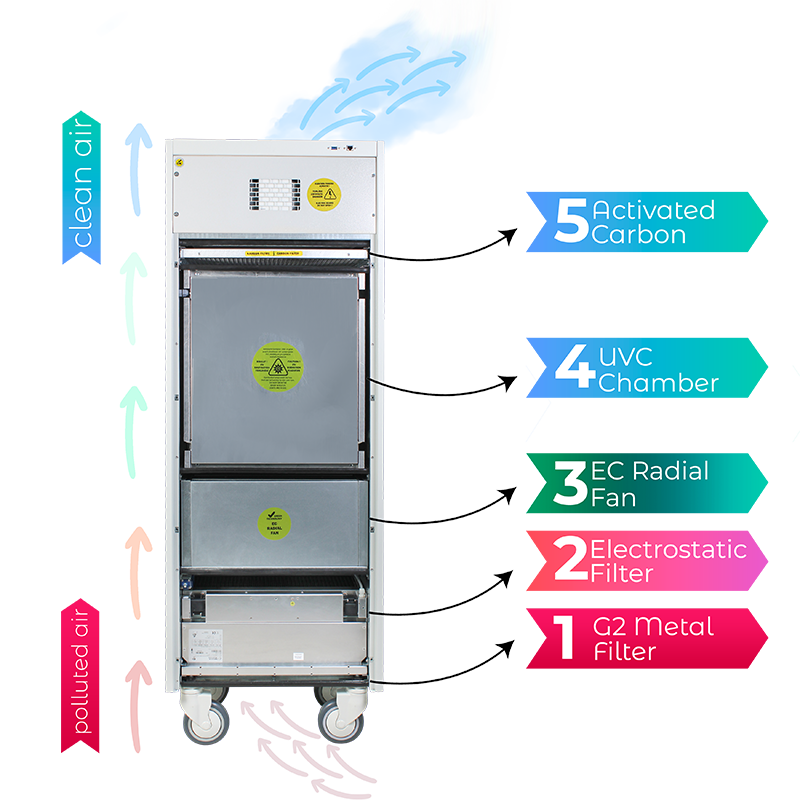

• Thanks to its high collection efficiency of submicronic particles and to its strong electric field, the ESP filter has an elevated antibacterial power and is active on pollen,

fine dust, toner, mold, smog, viruses, bacteria and tobacco smoke.

• The special high dosage UV-C lamp in the HV kills bacteria, viruses, moulds and other primitive organisms in a safe and efficient manner.

• Activated charcoal is an absorbent filter that will retain certain vapors passing through it to filter odors or chemical gases which kept viruses hanging in the air for a long time.

Additional Benefits ;

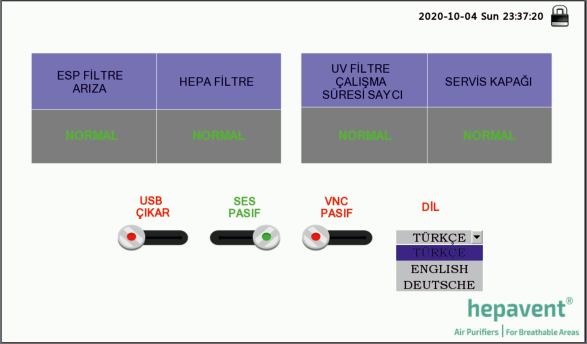

• The integrated PLC control will make its use and programming

• Filters status and alarms on screen

• Plug & Play, Easy to install

• Easy to service and cleaning

• UVC filter life counter/alarm

• Low pressure drop – the air flow through the filters is maintained for a long time

• EC type high efficiency fan with variable speed control

• Double panel insulated with 30mm thick rock wool and silencer

The HV EU offers a low Life Cycle Cost (LCC) thanks to low energy consumption, long life of the air filters, minimal downtime and low service costs.

Application ;

While HV EU air cleaners are used in areas such as HV models, they are additionally used in places where the risk of virus and disease transmission is very high like hospitals.

It is preferred in busy areas where long-term use and long filter life is required.

For Healthcare

facilities

Record Indoor Air quality Data to avoid risks

Why we suggest Smart Control ?

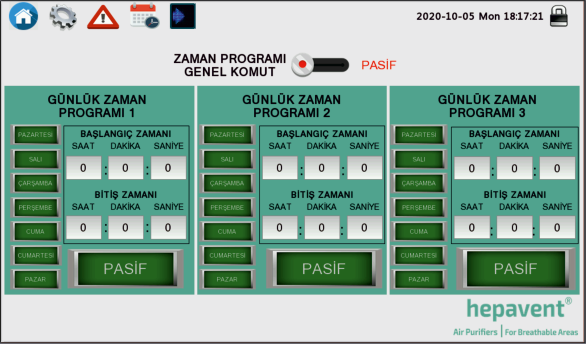

JUST TOUCH IT TO CONTROL IT : The intelligence of the Smart Control is easily and intuitively controlled via the touch screen’s user interface. Smart models have precise PM2,5 sensor measures the number of particles in the air. So you can datalog air quality with 7″ touch panel control unit. When in automatic mode, the ventilator adapts to the current air quality indicating with;

The integrated smart display also indicates the maximum partical size currenlty being filtered as well as the remaining lifetime of the filter.

The fine dust room sensor is designed

to measure and transmit indoor

concentrations of PM2,5

(Concentrations of fine particulate matter)

Specifications ;

* 7″ Touch panel

* PLC control

* Air quality indicator PM2,5 (Fine Dust Room Sensor)

* Datalog transfering with USB port

* PC connection with RJ45 cable

* Particle measurement and storing particle data monthly / yearly

* Automatic working mode according to air quality (PM2,5)

* Time schedule

* Password protection

* 6 speed fan control / Auto mode

* ESP filter status/alarm

* UVC filter life counter/alarm

Monitoring and Datalog

the Concentrations of fine particulate matter

Monitoring allows air quality specialists to collect data on interior conditions, identify source issues, and formulate solutions for mitigating problems.

Monitoring can also serve to ensure that solutions have been successful.

USB 2.0 interface, You can transfer data to USB stick

Logging rate: 15 seconds

LCD confirms logger operation and displays near real-time measurement data

On-screen alarms notify you when a sensor reading exceeds set thresholds

When memory full, automatically delete first date & time

Factory calibrated

And this is how you get to further information:

For more detailed information on Hepavent, simply download the brochure.

HOW IT WORKS

%99,995

Kill viruses with Hepavent Air Purifiers

Electrostatic Filtering Technology

The efficiency of bacterial elimination is 98-99% ;

* Airborne bacteria, like Micrococcus luteus

* Yeasts like, Rhodotorula rubla

* Bacillus anthracis

* Molds and microbes present in natural air spectrum

The Hygiene Institute of Berlin has certified that electrostatic

filters are able to remove from the air the airborne bacteria,

yeasts and molds with an efficiency between 98% – 99%.

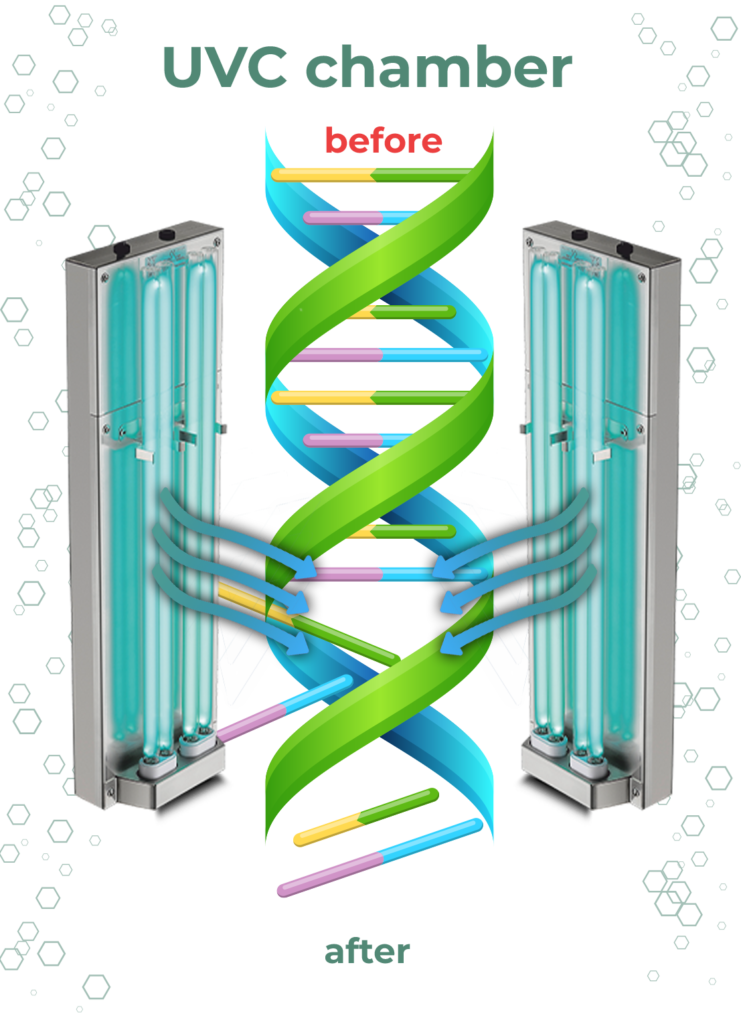

Germicidal UVC Lamps

To prevent this, we filter with Hepavent UVC lamp chamber;

• Prevention of germ contamination in HVAC systems up to 99%

• Ensuring the hygiene requirements of VDI 6022

• Ensuring working and test conditions in laboratories

• Reduce the risk of contamination in office administration buildings and meeting places

• Almost maintenance-free

• UV disinfection has many advantages over chemical disinfection. It does not produce toxins, volatile organic compounds and dangerous by-products.

• With UVC lamp, which radiates at 253.7nm wavelength in Hepavent, it inactivates by attacking the DNA of bacteria, virus, amplicons and other microbes emerging after PCR. UVC light penetrates the microorganism cell content and disrupts the structure of the DNA molecule. It does this by destroying genetic information in DNA.

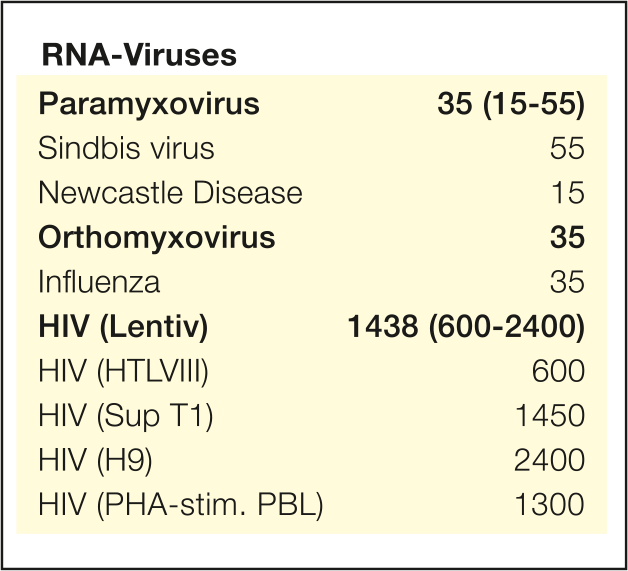

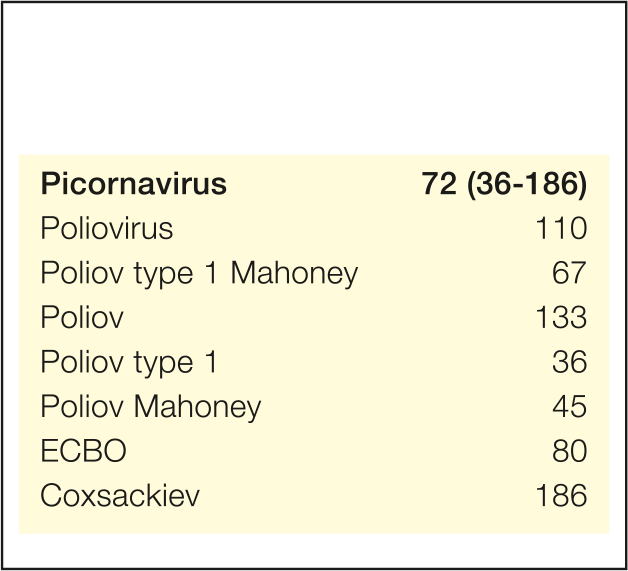

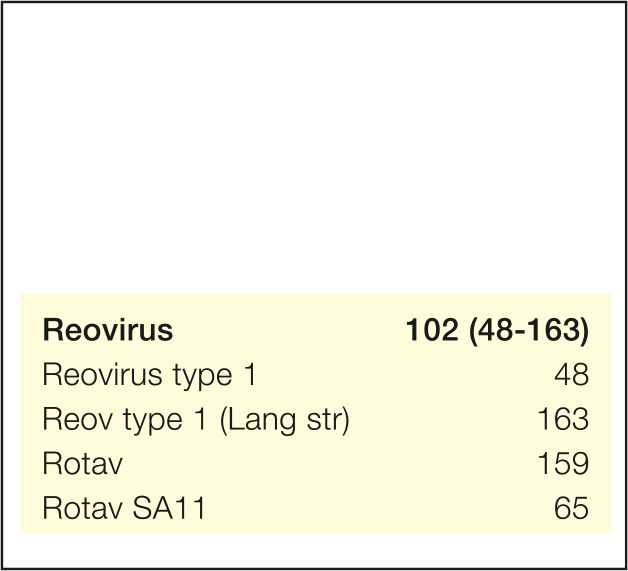

Radiation Doses for Inactivating Various Viruses

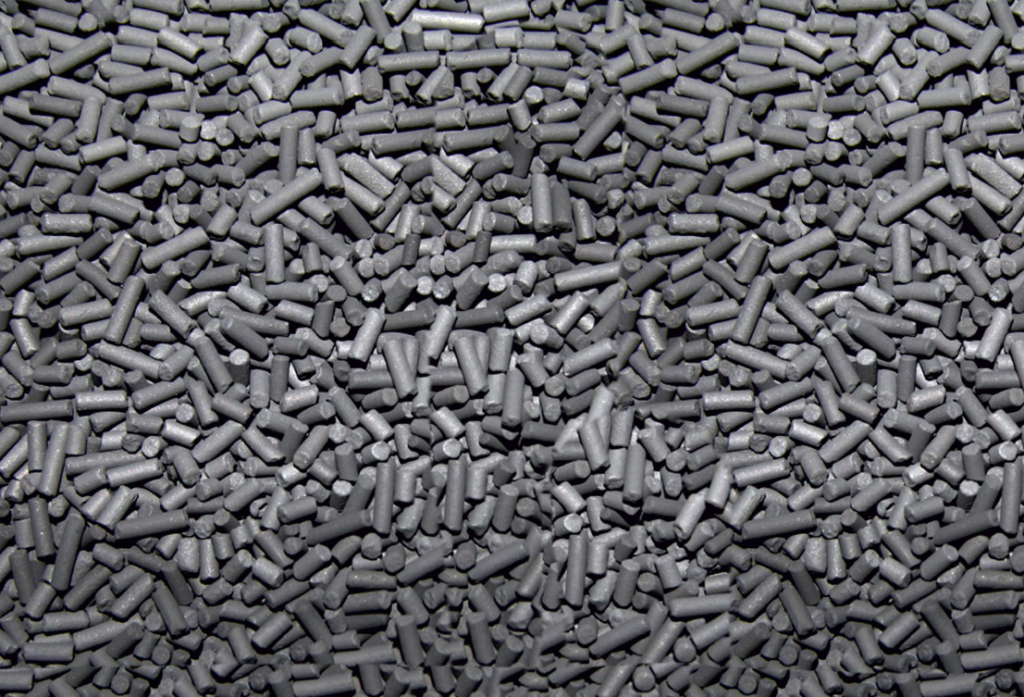

Activated Granule Carbon

Indoor Air Quality is Critical to Patient and Worker Safety

The air inside your building can contain:

• Moulds, spores, pollens

• Carbon monoxide, radon, volatile organic compounds (VOCs)

• Bacteria, viruses and by-products

• Vehicle engine exhaust, exhaust from industrial plants

• Asbestos, clays, elemental particles and man-made fibres

Activated carbon has special properties that allow it to remove volatile organic compounds (VOCs), odors, and other gaseous pollutants from the air. It

accomplishes this in a way that is different from other air purifiers like HEPA that only filter particle pollution from the air. Carbon air filters trap gas

molecules on a bed of charcoal, a process that has a surprisingly colorful history. Here you will dive deep into how they work.

The UVC frequency is not the type of UV that creates ozone and hydroxyls. This means that the UVC will not treat odours and volatile organic compounds on

the airflow. The carbon filter stage however will capture these gaseous contaminants without the use of ozone.

Media is composed of a combination of activated alumina and other binders, in spherical, porous pellets. Potassium permanganate is impregnated to this

media combination in order to provide optimum adsorption, absorption, and oxidation of various gaseous contaminants. Potassium permanganate is applied

uniformly during pellet formation and is distributed throughout the pellet volume. This process provides the maximum amount of impregnant for chemical reaction

and optimal performance. Targets acidic gases, volatile organic compounds, deactive molecular weight organics.

Target contaminants include;

• Formaldehyde

• Hydrocarbons (VOCs)

• Hydrogen sulfide

• Lower molecular weight aldehydes and organic acids

• Nitric oxide

• Nitrogen dioxide

• Sulfur dioxide

Our gas phase filters provides a stronger adsorption capacity for compounds (such as hydrogen sulfide, mercaptans, sulphur dioxide, chloride,hydrogen chloride, nitrogen

oxides, formaldehyde and ammonia) which are not adsorbed as strongly by general active carbon filters. System’s gas phase carbon filter can be used for a broad range

of chemicals. The load factor capacity index shows the approximate amount of toxic substance which the filter can adsorb. When a 10 kg filter has an index of “4”, it

means that up to 50%, i.e. 5 kg toxin can be adsorbed.The index doesn’t indicate the filters efficiency and the approximate weight of contaminant which can be adsorbed.